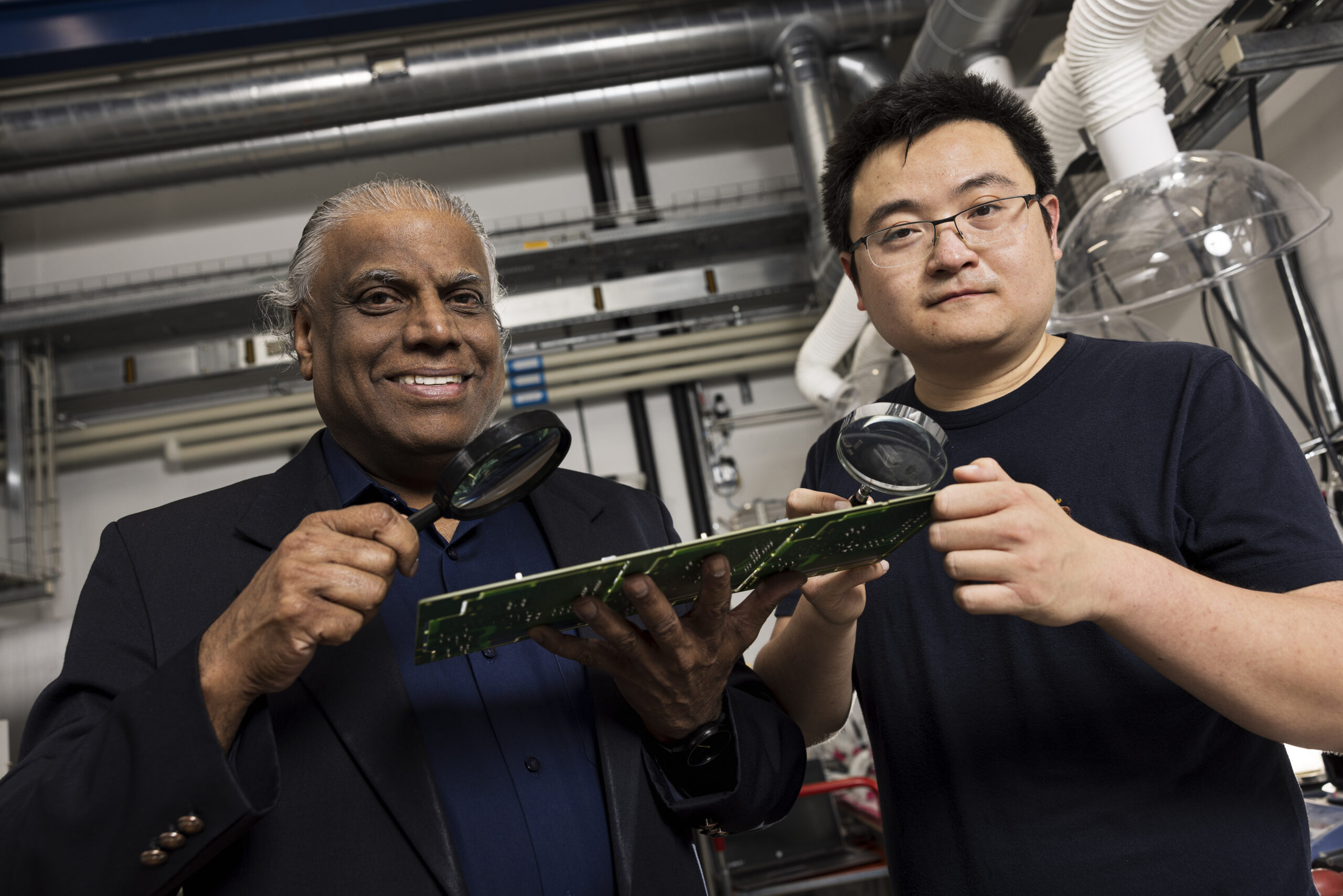

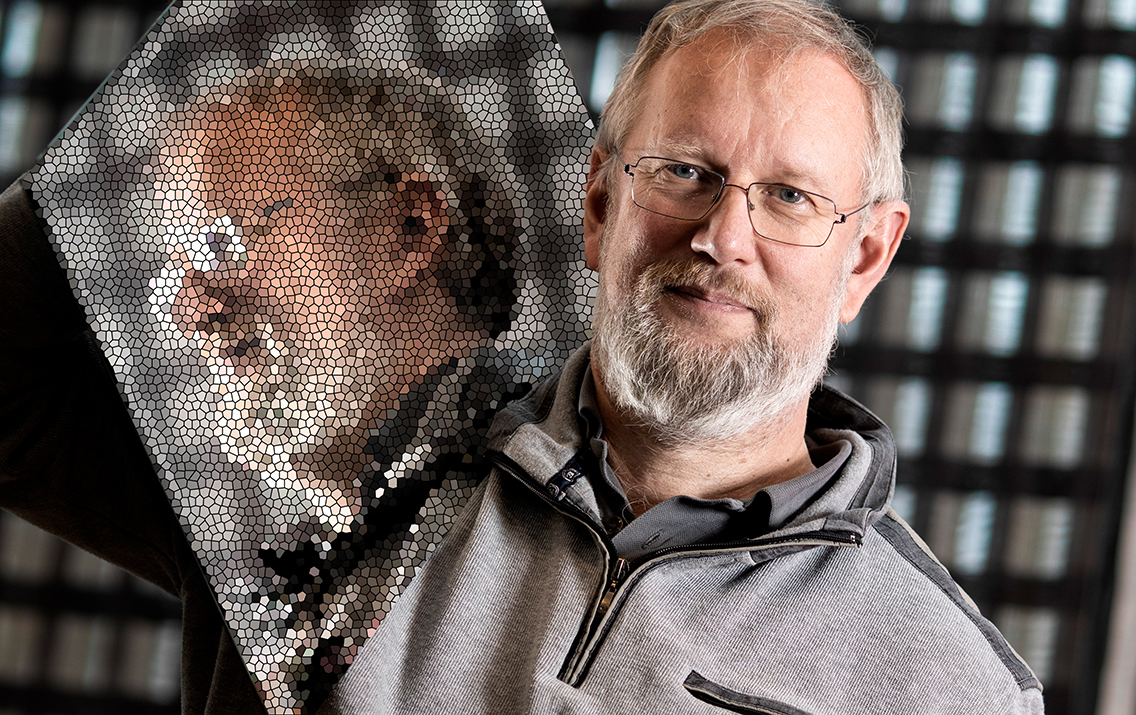

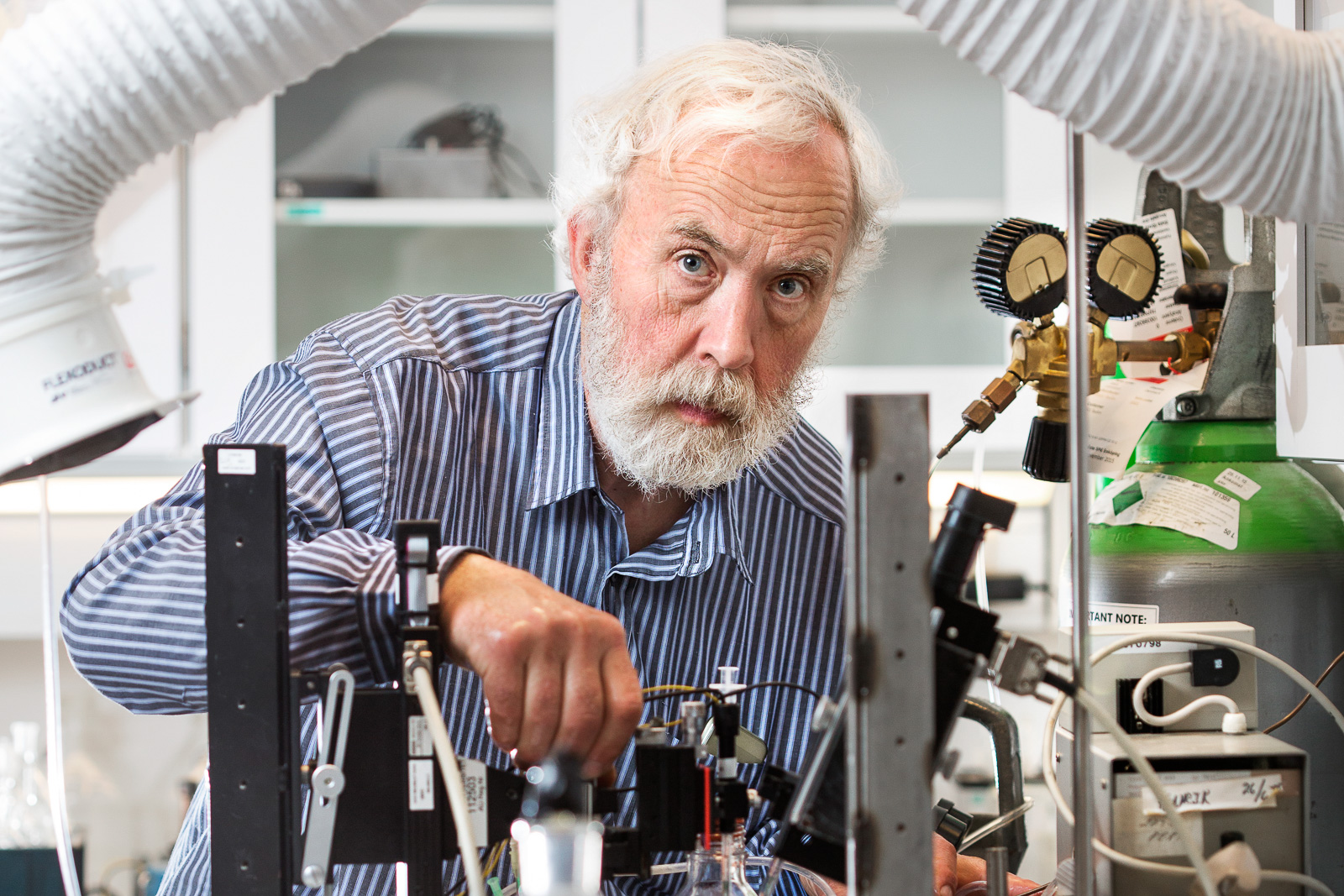

David Bue Pedersen, who heads up the DTU 3D printing research group, has received a grant for a 5-year research project perfecting the the processes behind 3D printing technologies – especially when it comes to geometric precision and mechanical applications. The project will cover 3D printing with both metal and plastic, more commonly known as additive manufacturing.

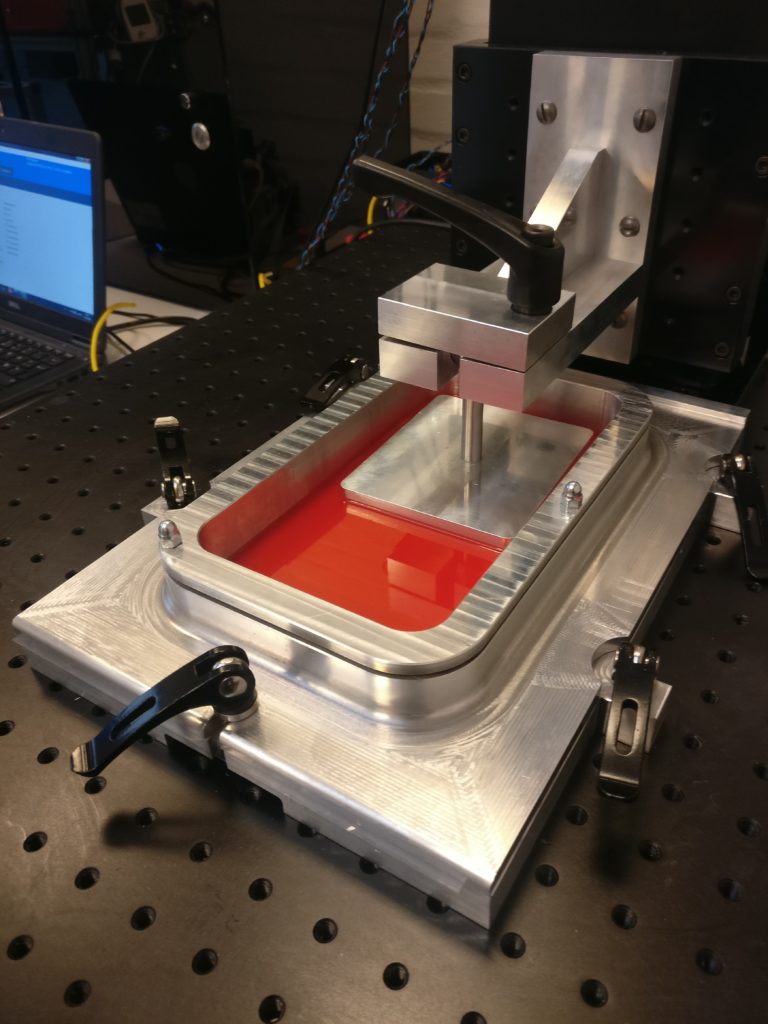

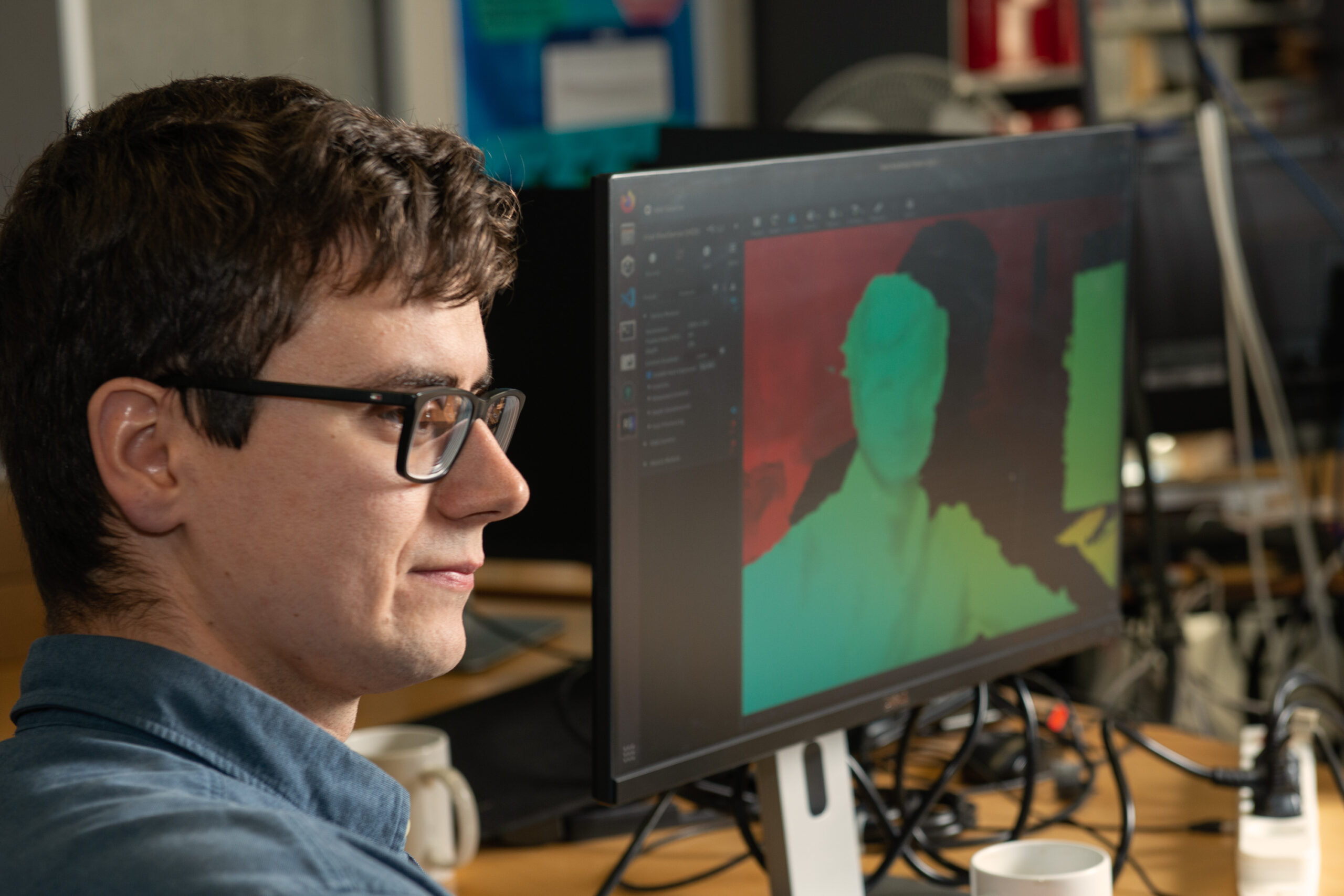

The project will describe physical snd digital systems behind the two most popular industrial 3D printing methods within metal and photo polymer printing via a modularisation of the processes. Afterwards, an open architecture will be created and all documentation behind the architecture (hardware, electronics, source codes will be made publicly available, allowing researchers and industry to drive further development within this field.

Research in 3D printing is on the rise, albeit concentrated on design and materials as well as quality assurance.

These skills are all present in the DTU research group and will push existing state-of-the art within 3D-printing.